20 Jul A Complete Guide to Class A Decking

Introduction

Since the 2018 change in Building Regulations, which were brought about by the Grenfell Tower tragedy, any residential high rise above 18m is banned from using combustible cladding. Similar regulations towards external flooring were also introduced, which means that high rise external flooring construction must specify class A rated decking systems.

In February, we heard from the UK Housing Secretary that the government was announcing an unprecedented £5 billion investment into building safety. They will fully fund the removal and replacement of unsafe cladding on residential buildings of 18m or above (6 storeys).

At this time, the Grenfell Inquiry is ongoing but recent news reports have highlighted how the business responsible for the Tower’s cladding had insisted they had no control over the type of materials specified. They claim that it was for architects to decide whether they met fire safety regulations.

As architects in charge of decisions regarding building design and safety, being on top of the current statutory regulations is of utmost importance.

In this article we will cover:

- What is Class A Decking

- What are the Regulations Around Class A Decking

- How are Construction Materials Fire-Tested?

- A1 and A2 Fire-Rated Materials

- Why is Class A Decking Important?

- What Surface Materials Deliver Class A Decking?

- Mistakes to Avoid with Class A Decking

- What Pedestals to Use for Class A Decking

- Individual Pedestals v.s. Rail-Based Systems

- Conclusion – Alfresco Floors Class A Fire-Rated Solutions

What Is Class A Decking?

Class A decking is external flooring that has been fire-tested to meet current building fire regulations and has been classed as non-combustible and therefore safe and legal to use on high rise residential buildings above 18 metres (11 metres in Scotland).

It is important to note that both Class A1 and A2 can be specified on a high-rise attachment above 18 metres.

For a flooring solution to achieve a European Standard BS EN 13501-1 Class A fire-rating, it must pass tests for its combustibility, burnability, and smoke ability. The Class A rating is the highest of fire ratings, ranging from A to F. If a material contributes to the spread of fire or smoke in the event of a blaze, it, therefore, would not be classed as safe.

The current UK Building Regulations state that high rise residential buildings (over 18m) must be constructed with non-combustible materials, including decking on balconies, roof and winter gardens, and other external attachments. If standards are not met, penalties can be issued from a fire inspector.

Class A decking is extremely important in order to protect the lives and homes of people living and working in high rise buildings. However, the rules surrounding non-combustible materials do not mean that specifiers are limited in their choice of design and style.

Class A external decking still comes in a variety of sizes, shapes, and colours. You can create stunning external flooring solutions with materials that are attractive as well as practical: weather-resistant and non-combustible.

What Are The Regulations Around Class A Decking?

The current building legislation that concerns external flooring such as decking is The Building (Amendment) Regulations 2018 (S.I. 2018/ 1230) and amended Approved Document B and Approved Document 7 Guidance.

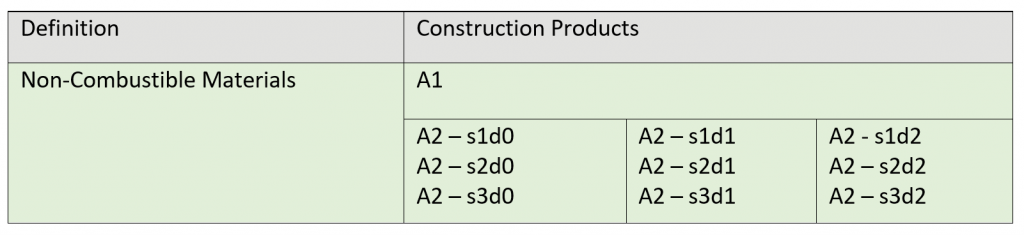

This set of Class A regulations bans the use of combustible materials on high rise buildings (18m) on external walls, and specified attachments (balconies). Any materials specified in such systems must be A2-s1, d0 rated or Class A1 under the European classification system (Euroclass) set out in the standard BS EN 13501-1.

The high rise buildings in question include any building above 18m that is used for residential purposes, whether an apartment block, student accommodation, care home, hospital, or boarding school.

The ban focuses on new build constructions, meaning current buildings do not have to be retrofit to meet the current standard. However, this also covers refurbishment projects as well as building conversions.

How Are Construction Materials Fire-Tested?

The classification system is defined in BS EN 12501-1. It is recognised as the primary standard within the construction industry and involves a combination of up to five rigorous tests. These tests are designed to assess a product on a range of characteristics including heat levels, combustibility, flame spread and smoke release.

The Euroclass Testing methods are stringent and closely monitored – thereby providing manufacturers, architects and specifiers with confidence and assurance.

The BS EN 13501-1 classification comprises three ratings:

1.Euroclass Rating

The first is the Euroclass Rating and the subsequent abbreviations as follows:

Euroclass rating – which will be the letter A1, A2, B, C, D, E or F

*Flooring materials are followed by the abbreviation ‘fl’ (e.g A1fl)

2. Smoke Emission During Combustion

The second classification relates to smoke emission during combustion. This is indicated by an s1, s2 or s3 rating – from highest to lowest performance. It’s important to note that smoke emission classifications are not provided for products with an E or F rating.

3.Production of Flaming Droplets/Particles

This rating is indicated by d0, d1 or d2 from highest to lowest performance. E-rated products receive a d2 flaming droplet classification.

It’s important to note that A1-rated products aren’t given a smoke emission or flaming droplet rating. This is because they do not contribute to fire growth or spread.

A1 And A2 Fire-Rated Materials

The most stringent tests – as highlighted above – must be passed in order for construction products to reach a Class A rating. When decking materials pass the fire tests for Class A, they will be rated as either Class A1 or A2 and will be able to be specified as part of a decking system.

Some Class A1 rated products do not require fire safety tests as they are made of materials that are intrinsically non-combustible. Examples of these include aluminium, natural stone, concrete and porcelain.

However, these materials are only ‘naturally A-rated’ if they haven’t been treated in any way. For example, applying a powder coating to aluminium may affect the fire performance rating.

Below is a table to demonstrate the testing criteria which grants materials with an A2 rating.

Why Is Class A Decking Important?

Any residential building over 18m in height must specify non-combustible decking for all specified attachments i.e. balconies. This means any materials specified on these must be fire-tested in order to confirm they do not burn or contribute to the spread of fire or smoke.

As Class-B rated materials are only fire-resistant and can still combust under certain conditions they are not permitted on residential buildings of 18 metres or higher, meaning Class A fire-rated flooring materials are the only solution for specifiers.

Non-combustible decking for high rise balconies, roof gardens, or other external attachments, are extremely important for the safety of residents and visitors in high rise buildings.

Class A decking and subframes limit the spread of fire and smoke in the event of an emergency, keeping exit walkways safe for people, and allowing firefighters access, fast.

However, the stronger, and safer, regulations have restricted the use of commonplace and easily available decking materials such as timber, GRP, composite decking and polyester resin. These materials are combustible or are not Class A1 or A2, and therefore no longer appropriate or safe to specify.

Class A Non-Combustible Decking & Subframes

Don’t forget that the whole system needs to be Class A-rated, not just the decking surface material. The subframe and joists must also be non-combustible, as each component works together to create a whole system flooring solution.

Just as important as the decking material, the decking subframe and pedestals must also be non-combustible (Class A rated). Choosing a non-combustible decking system is critical.

For example, if non-combustible porcelain tiles were laid on a combustible decking pedestal system, the balcony or roof garden is still at risk of contributing to the spread of fire.

What Surface Materials Deliver Class A Decking?

Materials such as porcelain, concrete, metal, and stone are naturally non-combustible and would meet the conditions of the Class A fire-rating.

What Flooring Solutions are Class A Fire Rated?

What are your options for Class A External Flooring?

EUROCLASS A1 EXAMPLES

- AR-Pave for porcelain & concrete pavers

- A-PED ™ Pedestals

- REIF DuraLink ®

- Porcelain Tiles

- Concrete Pavers

- Natural Stone Pavers

- Metal Components (such as steel)

EUROCLASS A2 EXAMPLES

- Powder Coated Aluminium Decking

- Materials Containing Small Amounts of Organic Matter

STONE PAVERS

Stone paving is a great solution for those aiming to achieve a modern, yet rustic and natural look. The texture and appearance make the natural stone paving truly stand out – whether you opt for Yorkstone or Granite.

CONCRETE PAVERS

Concrete is a great solution for those wanting to cover a large surface area. It is often the material of choice for those seeking a more practical solution. Alfresco Floors offer the Carreau and Rockstone ranges which can be personalised with bespoke colour options.

PORCELAIN PAVING

Porcelain is a popular choice due to its versatility and durability. Porcelain pavers are very strong due to the high heat they face during the manufacturing process (usually fired in a kiln higher than 700 degrees Celsius.)

Made from clay, porcelain tiles can be relatively thin (20mm) compared to other paving whilst still maintaining its hard-wearing characteristics. This makes porcelain lighter than concrete and stone pavers.

Porcelain offers an impermeable scratch resistant surface means that it will never fade, stain or corrode. Additionally, it doesn’t allow unsightly mould or moss to grow as it is non-porous. This is important when we consider external flooring as the more water-absorbing a material, the more maintenance and care needs to be taken with it.

When supported by an aluminium sub-frame, porcelain pavers are incredibly resilient and capable of high-load bearing, perfect for high traffic areas.

One of porcelain’s best features is its versatility. It can be manufactured in many ways to achieve a range of aesthetic finishes, including emulating other decking options, from concrete to wood.

A quick note we would like to finish on is that when it comes to specifying porcelain, not all porcelain is created equal. For ultimate quality and longevity, we recommend Italian-made porcelain pavers.

ALUMINIUM DECKING

Aluminium Decking is a great surface material for your external flooring. It is a naturally Class A fire-rated material so is a safe and effective option.

Aluminium is a lightweight metal, but despite that, it is more than twice as strong as other comparable external flooring materials. It’s resistant to scuffing and scratching, especially important on terraces and balconies where furniture might be moved about regularly.

Aluminium is also naturally corrosion-resistant, even in extremely harsh environments. When powder-coated, its longevity only increases, whilst also providing the options for different colours or textures.

Finally, aluminium is also recyclable as well as readily manufactured from recycled materials, giving it remarkable sustainable credentials. As a lightweight metal, aluminium is also easy to transport, reducing environmental impact and cost of transportation.

Key Characteristics to Look Out for When Specifying Aluminium Deck Boards

Now you know the key benefits of aluminium, it’s good to make sure when looking to specify one, you consider these key questions:

- Is it Class A Fire-Rated? Or does it use anti-slip coatings or rubber inserts that compromise fire-rating?

- Does it feature integrated water management?

- Does it have low slip-potential?

- Is there a guaranteed long-term performance?

- What are its thermal properties?

Mistakes To Avoid With Class A Decking

An important part of specifying any decking is how it looks, and how it fits into the overall aesthetic of the building and environment. But that’s not all you need to consider when it comes to building over 18m.

Here are the top mistakes specifiers and architects must avoid when it comes to choosing Class A decking that meets regulations but also strikes a balance between aesthetics, function, form, durability, and cost-effectiveness.

Mistake #1 11 Metres Or 18 Metres?

Due to current UK regulations, any residential building over 18m in height must specify non-combustible decking (which means it is Class A) for all specified attachments. However, in Scotland, the regulation applies to any building over 11m.

The 11m threshold may soon come into regulation as it will cover buildings above six storeys, but as of writing, this is not yet the case.

Regardless, there are no real reasons (including cost and aesthetics) not to consider using the highest-rated products available, even if they are not required by regulations at the time.

You can read more about this topic in our blog: 11m or 18m: What Is The Current Guidance For Fire Regulations?

Mistake #2 Only Considering Class A1 Products

Materials such as porcelain, concrete, metal, and stone are naturally non-combustible. This means that construction products made entirely of these materials can be classed as A1-rated without the need for further fire testing. Other products must be tested and certified as either A1 or A2.

When specifying external flooring, keep in mind both of these types are considered safe and are legally permitted on external applications of buildings of any height.

Mistake #3 Using Non A-Rated Sub-Frames

When choosing a Class A surface material, it is vital you make sure the entire decking system is compliant with fire safety and building regulations by ensuring it is completely Class A-rated.

The decking surface materials plus the joists, pedestals and accessories such as shims and spacer tabs, must also be non-combustible and meet a Class A fire rating.

This will ensure you specify a fully compliant decking system that meets fire safety and building regulations for high rise external flooring, whether a balcony, terrace or roof garden.

Mistake #4 Slip Resistance

For external attachments, slip resistance is important due to the safety hazard that can be introduced in wet weather. When specifying Class A decking ensure your surface material either has a slip-resistant coating added or that a slip-resistant insert is added into the deckboard.

However, once again, make sure that any use of combustible material i.e. a rubber insert, isn’t specified, as this will not be permitted on Class A decking.

We recommend, therefore, opting for a slip-resistant coating, as it should mean that the product remains Class A rated whilst still being an effective anti-slip option.

What Pedestals To Use For Class A Decking

When specifying external flooring applications, fire-rated pedestals are a key component in the delivery of a safe but attractive high-rise balcony or terrace.

For external flooring to be fully compliant with UK fire safety regulations, all of the individual components specified must meet at least Class A2 – s1 d0 rating against the European Standard BS EN13501-1.

The pedestals, whether included in the decking system you choose or which you specify individually, must be engineered to the highest standards of safety and meet the Class A rating.

Here is a selection of considerations you should make before specifying Class A pedestals:

- Non-combustible to BS EN 13501-1 fire classification and Euroclass A fire-rating

- Designed and engineered for external flooring whether paving or decking

- Fully adjustable pedestal system to support a terrace or balcony structure

- Withstand standard weight requirements

- Strong, durable, and long lifespan

- Allow quick run-off of water

- Corrosion-resistant and sustainable material choice

Pedestal Accessories

It is also crucial that pedestal accessories should also be made of appropriate A-rated materials. You do not want to compromise fire-safety with plastic or rubber shims or spacers, for example.

Unless the material is naturally non-combustible, such as metal, you will need to ensure certification to show that the component does not contribute to the spread of fire or smoke.

Individual Pedestals v.s. Rail-Based Systems

There are many similarities and differences between adjustable pedestals (such as the A-PED) and rail/joist systems (AR-SYSTEMS & REIF DuraLink), as they both fulfil the same function: supporting the application of raised floor areas.

Paving

If your proposed external flooring area incorporates ‘unusual’ paver layouts, rail-based systems are the more appropriate solution. Challenges may include a ‘tight’ shaped area where lateral movement of tiles might be an issue, for example balconies.

In this instance, our AR-PAVE system uses side-stops/end-stops to hold tiles in place perfectly. It also ensures that a minimum perimeter gap is maintained to facilitate drainage and meet any minimum-gap requirements.

However, more regular areas may not require the heightened functionality that a rail-based system provides, and therefore a individual pedestal would be a more appropriate and cost-effective solution.

In some cases, your paving project may have a mixture of complex and regular areas. It is possible, in this case, to mix systems – another way of reducing overall cost.

Due to the volume of aluminium that is used in a rail-based system, it can be a more expensive product to purchase but the reduction in relative install-complexity can see labour costs reduced.

Decking

Build up for decking will always consist of a pedestal and joist in one format or another.

Since aluminium decking is always ‘clipped’ to a joist, it needs to be used with a compatible joist system. For example, the AR-DECK system comprises of aluminium deck boards and joists, providing a complete solution.

Rail systems are designed to work together – note that AR-SYSTEM joists are designed to work with AR-SYSTEM pedestals as well as A-PED pedestals. It is possible to mix and match systems to get the optimum solution for your unique areas.

Again, a rail-based system is good for unusual-shaped areas in which lateral movement might be an issue.

Conclusion: Alfresco Floors Class A Fire-Rated Paving and Decking Systems

Alfresco Floors are the UK’s most established specialist in the provision and installation of pedestal-based external Class A fire-rated floor systems. We are aware of the huge gap in the UK supply chain to the UK construction industry for quality fire-rated external flooring systems that meet the current regulations and want to fill that gap.

Meeting the demands for a fully fire-rated external decking solution, the

We provide a complete and comprehensive service to the market and have three Class A-rated sub-frame systems: A-PED Class A Adjustable Pedestals, REIF DuraLink and AR-System (AR-Deck and AR-Pave.)

Alfresco AR-system: AR-Pave and the sub-frame of AR-Deck is composed 100% of aluminium, and therefore does not require a fire safety test. As specialists in Class A fire-rated solutions, our products do not contribute to a fire at any stage – making them the safest option for your high-rise project.

AR-Deck from Alfresco Floors is a 100% aluminium decking system, comprising of deckboards with a fully adjustable pedestal and joist sub-frame. Designed and manufactured in Britain, AR-Deck has been developed specifically to meet the requirements for non-combustible materials on balconies and other outdoor spaces, delivered at a competitive price and short lead times.

Class A1 AR-Pave from Alfresco Floors is a 100% aluminium sub-frame system designed for rectified pavers in porcelain or concrete. Like the AR-Deck, it is adjustable in height and can compensate for slopes up to 5%.

We also supply a large variety of Class A-rated surface products: aluminium decking, porcelain tiles, concrete and natural stone pavers.

The team at Alfresco Floors have unrivalled experience in exterior flooring. We are experienced in all sorts of technical challenges and just about every type of ‘raised floor’ installation system. We focus our efforts exclusively on the products and solutions that we know offer the best combination of not only fire safety but price, prestige, and practicality.

If you would like any more guidance on what systems are best suited for your needs, the technical experts at Alfresco are on hand to give site-specific advice and advice as to which systems will work best.

With decades of experience and a portfolio of impressive projects, why not choose Alfresco Floors as your next partner in delivering a fully A-Rated external flooring solution?

To find out more about our products, call us on 020 8977 0904 or fill out the form below.

Sorry, the comment form is closed at this time.