27 May The Dilemma for any Landscaping Decking Project… What material to use?

In the past, selecting the boards for decking or cladding projects came down to three options: tropical hardwoods, tanalised softwoods and wood/plastic composites. Advances in decking technology now mean that landscape architects have a wider choice of new materials.

There are currently four major categories of deck board and cladding designed for this sector.

Firstly, and keenly priced, is thermo-timber such as Thermo-Ash and Thermo-Pine. Thermo-treated timber is ‘cooked’ softwood. Vast kilns are used to heat the raw timber – a process which burns out all the sugars (to ensure there is nothing for mould and algae to feed on) and evaporates most of the moisture (to reduce the possibility of the boards expanding or contracting in extreme temperatures). A steam injected cooling process re-introduces just the right amount of moisture to stop the boards becoming brittle and the entire process creates a stronger, harder and more resilient timber.

Thermo-treated timbers usually come out of the kiln in various shades of light brown or rich chocolate (Thermo-Ash is particularly attractive) so they are ideal for luxury decking. As most of its moisture has been removed, thermo-treated timber is lightweight so loading issues are reduced when cladding large areas. As all the sugars have been cooked out, these timbers are guaranteed rot free for at least 20 years.

Pressure treated timber is another option. This category includes brand names such as Kebony, Accoya and most recently, Lignia. Compared with thermo-timber these boards are more expensive to manufacture and buy but can have lifespans of more than 50 years.

This category of timber is created by racking lengths of raw softwood inside air-tight chambers and then using a combination of negative and positive air pressure to force a complex concoction of preservatives into every cell of the wood, effectively replacing the original organic content with a dense and dimensionally stable new core. As the thermo-treatment, the process effectively turns softwoods into something closer to tropical hardwoods in terms of strength and resistance to abrasion – and with the right additives in the mix, these timbers can also be fire rated.

There is still a market for traditional hardwoods, though progress towards making these timbers sustainable over the last decade has reduced the choice and increased the price significantly. As a result, the use of conventional hardwoods for decks has recently dropped by at least 50% and that market is likely to be put under further pressure as competing materials get better at replacing the performance of hardwoods at a fraction og the ecological and financial cost.

Among the range of hardwoods available, IPE is still a popular choice and it weathers down to a robust and attractive silver-grey patina.

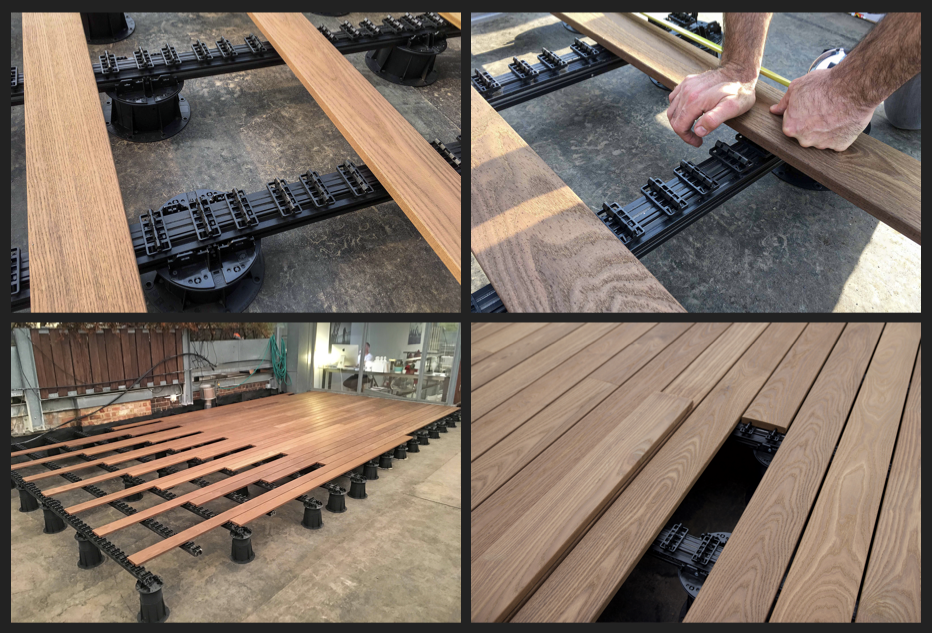

Finally, there is the rise of composite materials in the market such as Alfresco Grad. Composite decking in the UK is still only taking about 10% of the market from treated timbers, but that market share is doubling each year and is predicted to settle at around 50%.

The finest examples of modern composites are manufactured by what’s called a ‘co-extrusion’ technology. A conventional core of recycled wood and plastic materials is encased in a thin skin of more expensive pure plastic offering more opportunity for convincing colour, texture and higher resistance to damage or decay.

Compared to second generation composite boards, these third generation ‘co-ex’ materials offer double the manufacturing warranties (over 25 years) for about 30% extra on the cost. As with the latest technical timbers, both second and third generation composite boards can now be manufactured as fire rated products.

All timber deck boards will expand or contract in extremes of temperature r humidity. The latest technical timbers significantly reduce this tendency to ‘move’ and pure timber boards prefer to expand or contract only across their width, so it’s relatively easy to control with the right fixings. However, wood/plastic composites tend to expand along their legnth – normally by at least 1mm for every 1m of board – so they need to be installed and fixed more carefully. As traditional surfaced fixed screws are not ideal for the long length composite boards now available, side mounted clip systems have been designed which allow the material more freedom to swell and contract. Now ‘invisible fixing’ systems, like Grad, are available, where the clips are hidden under the board.

About Alfresco Floors:

Alfresco Floors are the UK’s leading specialist in the provision and installation of raised external floors for commercial and high-end domestic projects. From decking to paving, Alfresco floor offer an end-to-end service of technical design, materials supply and nationwide installation.

No Comments